关于厚度机械科技

|

历史沿革: 湖北厚度机械科技有限公司前身是湖北省英山县创兴塑机附件有限公司,成立于2003年,是一家专注于高精度吹膜机械风环、在线厚度检测和控制仪器生产、销售和技术服务的创新型企业。公司主要员工曾在湖北轻工机械厂、新中德、法国思肯德、德国赛默飞工作十余年,具有精湛德技术经验和服务意识。

人员构成: 我们的工程师凭借在国外测厚仪公司十余年工作过程中积累的丰富经验,结合国外先进算法以及进口核心部件,为客户生产高质量的在线测厚仪,同时开发了高效的控制软件,包括吹膜自动风环控制系统和流延自动模头螺栓控制系统(APC),在中国已有两百多套测厚控制系统在使用。公司以“创新为根本,服务为引导“作为宗旨。以”品质开拓市场“为动力,全力服务客户,不断创新。自动风环及成套控制系统在国内属于领先水平。 湖北厚度机械科技有限公司现在湖北黄冈进行风环本体设计制造、在广州花都进行测厚仪总装生产。公司生产技术人员30多人、售后调试人员十余人,团队技术素质高、服务意识强。售后服务人员随时通过远程监控,需要现场处理可在24小时内到达现场。

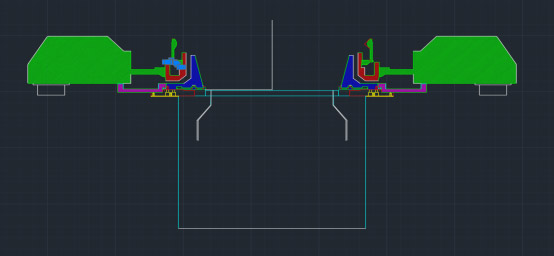

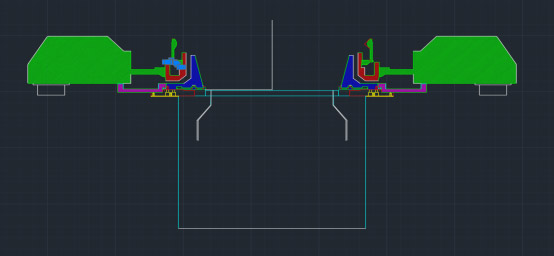

产品特点: W COOL-(350-550)是一种高效的具有双风唇的风环系统。 结合方便的风温式调整装置,对生产线的产量有明显的调高,并且对厚度公差有显著的改善。厚薄度误差相比无控制系统时降低50%,理论上极限偏差达到+-4%以内,2sigma值控制在2%-3%。 高效率吹膜生产线: W COOL-(350 -550)不但适用 于新的生产线,也可以用来提升现有生产线的性能。可以直接替换现有风环。

获得成功的准则 :自动控制风环,非常便利的厚度调整单元,专家团队评估生产线所有参数。 自动化:更安全的生产工艺 ,不再需要模头后中心校准,生产过程中自动调整厚度。

控制模块: 可靠,高效和易扩展。 可以得到什么?厚薄度误差相比无控制系统时降低50%,理论上极限偏差达到+-4%。 特殊的性能:挤出机的产量增加,在膜唇过渡期内,优异的熔体性能。可以适应不同模头的直径,可配置远程错误诊断功能,提高能效。

功能描述:调整加热元件可以让冷却空气温度发生变化在模头周向分布,对膜泡上厚点和薄点进行调整。 在膜泡被传感器测量厚度后,每个单元会通过算法函数进行即时调整。 精巧的设计:调整的控制是通过耐温的发热棒和散热单元进行的,全保护的结构设计防止机械组件受到任何污染,因此加热组件的维护变得更加简单。

Company history: Hubei Koodo machinery technology co., LTD., formerly known as hubei province yingshan county chong hing plastic machinery accessories co., LTD., founded in 2003, is a focus on high precision mechanical wind blown film thickness of ring, online detection and control equipment production, sales and technical services of innovative enterprises. Key employees and the company has in hubei light industry machinery factory, the new China and Germany, France, Kentucky Fried, Germany's fly work more than ten years, with superb technical experience and service consciousness.

The composition: Our engineers with thickness gauge of companies more than 10 years of work, accumulated rich experience in the process of combining foreign advanced algorithm and the core parts imported, for the customer in the production of high quality online thickness gauge, at the same time, efficient control software is developed, including wind blown film automatic loop control system and flow automatic control system (APC), die head bolt in China more than two hundred sets of thickness control system in use. Company to "innovation as the fundamental, service oriented" as the tenet. Develops the market by the "quality" for the power, to customer service, continuous innovation. Automatic wind ring and complete sets of control system belongs to the leading level in China. Now,Hubei Koodo machinery technology co., LTD. in hubei huanggang wind ring body design and manufacture, thickness gauge assembly production in guangzhou huadu. Company production and technical personnel more than 30 people, after debugging personnel more than 10 people, technical team with high quality and strong sense of service. After-sales service at any time through remote monitoring, need to deal with the scene can be arrived at the scene within 24 hours.

Product features: W COOL - (350-550) is a highly efficient with double outlet of wind ring system. Combining with convenient air temperature adjusting device, the production line have significantly higher yields, and has significant improvements in the thickness tolerance. Thickness deviation was 50% lower when compared with no control system, theoretical limit deviation of + - 4% less than, 2 sigma value control in the 2% to 3%. Efficient blown film production line: W COOL - (350-550) not only apply to the new production line, can also be used To improve the performance of existing production lines. Can directly replace the existing wind ring.

Success criteria: automatic control wind ring, very convenient adjustment unit, the thickness of the expert team to evaluate the production line all parameters. Automation: safer production process, no longer need to die after calibration center, automatically adjust the thickness in the process of production.

Control module: Reliable, efficient and easy to expand. You can get what? Degree of thickness error by 50%, when compared with no control system in theory limit deviation of + - 4%. Specific performance: the extruder production increases, the membrane lip is a transitional period, performance excellent melt. Can adapt to different mould diameter, configurable remote fault diagnosis function, improving energy efficiency.

Function description: adjust the heating element can make cooling air temperature change in the die head circumferential distribution, thick and thin on the membrane bubble point to adjust. After the sensor measuring the thickness of the membrane bubble, real-time adjustment for each unit will pass algorithm function. Sophisticated design: adjusting control is through the heat resistance of the hot rod and the cooling unit, the whole protection prevents any pollution of the mechanical components of structure design, so the heating component maintenance easier.

|

微信WeiXin

微信WeiXin